NEWS UPDATES

NEWS UPDATE-1

More Compact and Efficient Vertical Turbines Could Be the Future for Wind Farms

The now-familiar sight of traditional propeller wind turbines could be replaced in the future with wind farms containing more compact and efficient vertical turbines.

New research from Oxford Brookes University has found that the vertical turbine design is far more efficient than traditional turbines in large-scale wind farms, and when set in pairs the vertical turbines increase each other’s performance by up to 15%.

A research team from the School of Engineering, Computing and Mathematics (ECM) at Oxford Brookes led by Professor Iakovos Tzanakis conducted an in-depth study using more than 11,500 hours of computer simulation to show that wind farms can perform more efficiently by substituting the traditional propeller-type Horizontal Axis Wind Turbines (HAWTs), for compact Vertical Axis Wind Turbines (VAWTs).

NEWS UPDATE-2

Soft, Mechanical Metamaterial That Can “Think” Offers Potential of Helpful “Living” Machines in the Future

New soft, responsive metamaterial holds potential for wide variety of societal benefits.

Engineered, autonomous machines combined with artificial intelligence have long been a staple of science fiction, and often in the role of villain like the Cylons in the “Battlestar Galactica” reboot, creatures composed of biological and engineered materials. But what if these autonomous soft machines were … helpful?

This is the vision of a team of Penn State and U.S. Air Force researchers, outlined in a recent paper in Nature Communications. These researchers produced a soft, mechanical metamaterial that can “think” about how forces are applied to it and respond via programmed reactions. This platform holds great potential for a variety of applications from medical treatments to improving the environment.

“We created soft, mechanical metamaterials with flexible, conductive polymer networks that can compute all digital logic computations,” said Ryan Harne, James F. Will Career Development Associate Professor, Penn State. “Our paper reports a way to create decision-making functionality in engineered materials in a way that could support future soft, autonomous engineered systems that are invested with the basic elements of lifeforms yet are programmed to perform helpful services for people. These could include helping maintain sustainable and robust infrastructure, monitoring of airborne and waterborne contaminants and pathogens, assisting with patient wound healing, and more.”

NEWS UPDATE-3

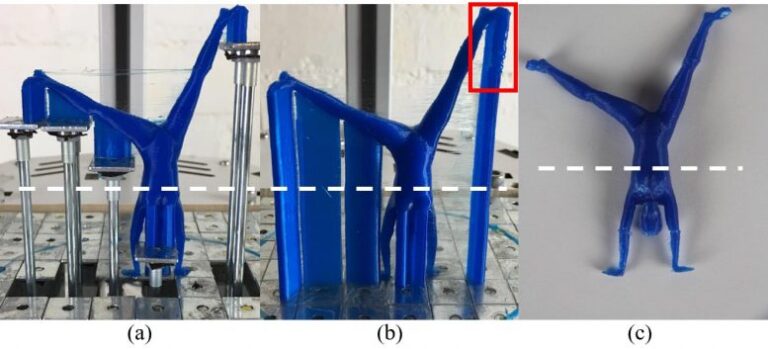

New Low-Cost Dynamically-Controlled Surface for 3D Printers Reduces Waste and Saves Time

3-D printing has the potential to revolutionize product design and manufacturing in a vast range of fields—from custom components for consumer products, to 3-D printed dental products and bone and medical implants that could save lives. However, the process also creates a large amount of expensive and unsustainable waste and takes a long time, making it difficult for 3-D printing to be implemented on a wide scale.

Each time a 3-D printer produces custom objects, especially unusually-shaped products, it also needs to print supports–printed stands that balance the object as the printer creates layer by layer, helping maintain its shape integrity. However, these supports must be manually removed after printing, which requires finishing by hand and can result in shape inaccuracies or surface roughness. The materials the supports are made from often cannot be re-used, and so they’re discarded, contributing to the growing problem of 3-D printed waste material.

For the first time, researchers in USC Viterbi’s Daniel J. Epstein Department of Industrial and Systems Engineering have created a low-cost reusable support method to reduce the need for 3-D printers to print these wasteful supports, vastly improving cost-effectiveness and sustainability for 3-D printing.

The work, led by Yong Chen, professor of industrial and systems engineering and PhD student Yang Xu, has been published in Additive Manufacturing.

Traditional 3-D printing using the Fused Deposition Modeling (FDM) technique, prints layer-by-layer, directly onto a static metal surface. The new prototype instead uses a programmable, dynamically-controlled surface made of moveable metal pins to replace the printed supports. The pins rise up as the printer progressively builds the product. Chen said that testing of the new prototype has shown it saves around 35% in materials used to print objects.